Why Remote and Centralized Device Management Is Transforming IT Operations...

Read More

Fast Facts

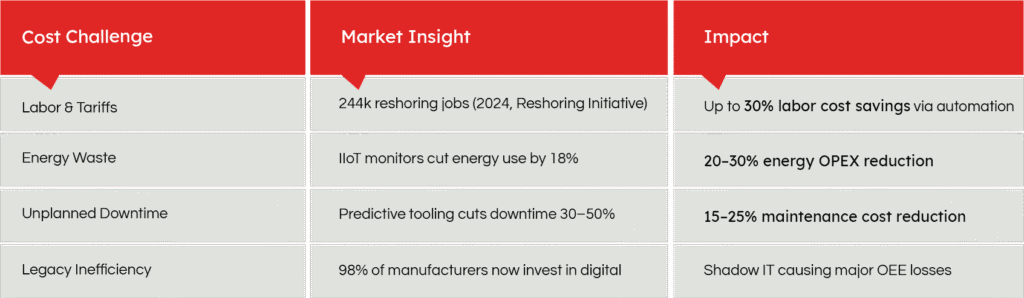

America’s industrial sector is undergoing a high-stakes transformation. In 2024, over 287,000 manufacturing jobs returned to the U.S. amid reshoring momentum, rising offshore costs, and geopolitical risk.

To stay competitive, CIOs and plant leaders must do more than adopt new technology—they must prove ROI.

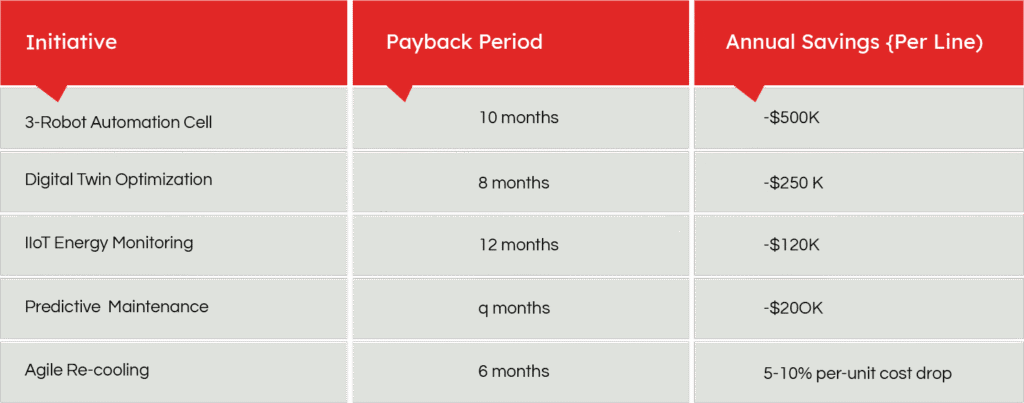

Enter: automation, IIoT sensors, digital twins, and predictive maintenance. These tools are helping manufacturers cut per-unit costs by up to 30%, improve resilience, and dramatically reduce unplanned downtime.

“One Tier-1 U.S. manufacturer reduced downtime by 28% in 90 days using Softenger’s IIoT automation pilot.”

Get a free remote infrastructure audit Deploy IIoT + automation on priority lines Validate ROI in real-time and scale for savings

Why Remote and Centralized Device Management Is Transforming IT Operations...

Read MoreGrid Modernization in the Energy & Utilities Sector: Building a...

Read MoreHome About Us Services Close Services Open Services IT Infrastructure...

Read More